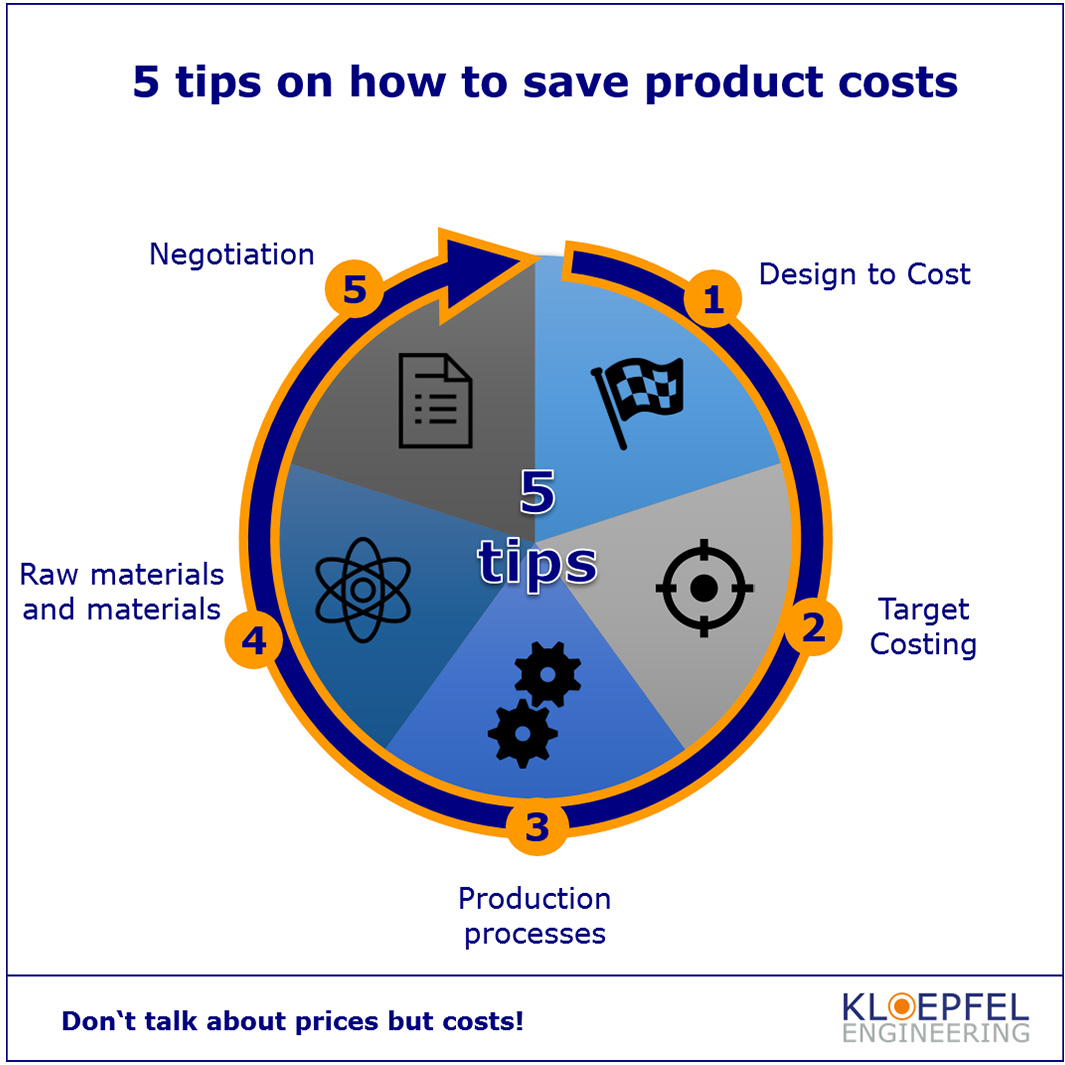

5 tips on how to save product costs

Reduce costs, increase product quality

The first sight of buyers and production managers is often at the price. In order to understand if this is justified, you have to know the costs. And you will quickly realize that there are still savings potentials left at some places. Above all, product costs are often true return treasures. We’ll reveal five tips on how you can sustainably lower your product costs without sacrificing quality.

1. Design to Cost

The Design to Cost approach not only focuses on the effectiveness of a product, but also on the efficiency. Designers mainly focus on the functionality of a product. A simple example: a designer wants to make a special connection between two objects with his component. A not standardized screw may do this job, but it costs a lot of money to produce it. By using the Design to Cost approach, it can be shown that a plastic screw, for example, can be produced more cost-effectively. The quality remains the same and the purpose is also fulfilled.

2. Target Costing

The second step deals with the question of how high the product costs can be in order to successfully market the product. One central question is here how much a customer is willing to pay for a product. But how do you get the target price, so that your company can achieve an optimal profit margin? The most efficient way is to use cost calculation tools. These decompose an element into its individual components and thus calculate the value. You receive a price and at the same time see what customer benefits your product offers. Products can thus be developed for a specific market at a desired target price. Of course, market conditions and prices may change, so you should not consider target costing as a one-time step. If you conduct the analysis regularly, you can adjust your product costs to the current conditions.

3. Production processes

There is not just one way of doing it. And this also applies for products or components – these can often be produced with different production processes. Production managers are thus facing the challenge of finding the production process which is effective and at the same time efficient. The key factor in the evaluation of the production processes is the cost-effectiveness of a production process: because you want to save product costs in the long-term and do not want to pay extra for the production from your own pocket. When evaluating whether the chosen or planned production process is (still) suitable, factors such as the acquisition cost of new machinery, retraining of employees and the possible increase in the number of pieces or shortened production times should be analyzed. Since time is also money, costing tools can help you to get a quick overview of whether and, if so which manufacturing process is better for your product.

4. Raw materials and materials

Product costs can be saved not only with the production process itself but also with raw materials and materials. In order to save costs at these points, without weakening the quality, there are several options available. Raw material and material savings can be realized, for example, through the Design to Cost approach by structurally changing a product. It is also possible that due to a modified manufacturing process less waste is produced during production. Sometimes, another material that has the same properties but is cheaper can lower product costs as well.

5. Negotiation

Especially in the B2B sector, prices are not transparent and often determined by the negotiation power of the purchasing department. Of course, you have to bring together everyone who is involved in the “reduce product costs” project. A key role is played by your suppliers. True negotiating kings know that valid arguments are the basis for a successful negotiation. Particularly convincing are numbers and facts, because these are difficult to refute. But how do you get these facts and figures? By using costing tools, you can understand if your prices are reasonable, regardless of your supplier, because you can see what the part costs the supplier in the manufacturing process at a glance. It’s not about pushing down prices, but about making the supplier more competitive. After all, a good relationship lives from transparency and honesty, and this also applies to business relationships. If you show your potential savings to your supplier, you have a sound basis for argumentation and you can also support each other better in global competition – a win-win situation!

Conclusion

There are many ways to save product costs. The five tips above provide an overview of what you can do to promote the project. Of course, not all named paths are suitable for every company, as they are associated with a different amount of employees and time effort. But an excuse that does not count is that you do not have time, because which company has no time to save costs?